Water treatment and testing

Find out how we treat and test our water to make it safe to drink.

We have 9 treatment plants across the region. Careful monitoring, testing and treatment makes sure the water is safe to drink.

We report on the quality of our drinking water in our Annual Drinking Water Quality Report and Monthly Water Quality Reports.

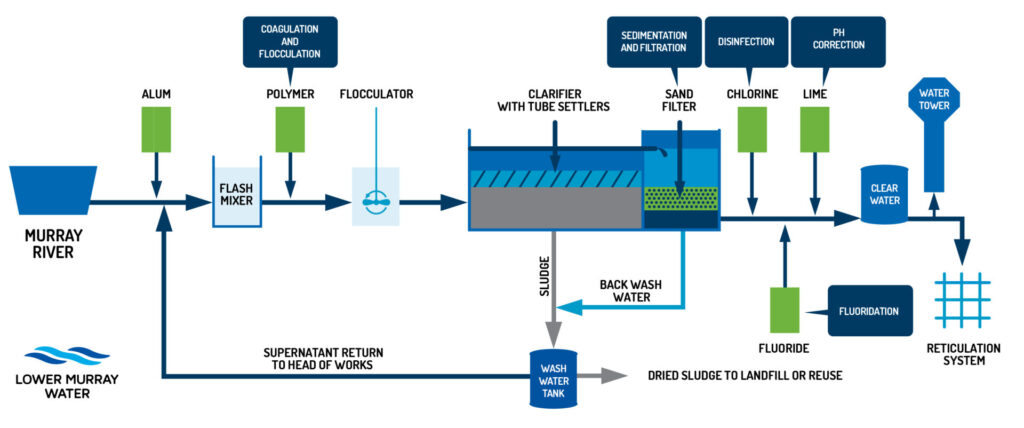

Water treatment process

Our treatment plants treat water to meet the national Australian Drinking Water Guidelines (ADWG) and the Victorian Safe Drinking Water Act 2003 (SDWA). Find out more about the steps in our water treatment process.

Step 1. Coagulation and flocculation

The first step of the conventional treatment process involves dosing a chemical coagulant to help gather suspended solids and organic material in the raw water.

We use aluminium sulphate and aluminium chlorohydrate to bring about the coagulation process, which helps to form particles called ‘flocs’. Floc particles develop to a larger size during flocculation. The larger size and weight of the floc helps with the sedimentation process (step 2).

Flocculant aids, including polyelectrolytes, are also commonly used to enhance the flocculation phase.

Step 2. Sedimentation

The purpose of sedimentation is to enhance the filtration process by removing particulates.

In the sedimentation process, suspended particles are removed from the water by means of gravity or separation.

Floc particles settle to the bottom of the basin while clear water passes out of the basin over an effluent baffle or weir. The solids collect on the basin bottom and are removed by a mechanical ‘sludge collection’ device which scrapes the solids (sludge) to a collection point within the basin. It is then pumped for disposal or to a sludge treatment process.

Step 3. Solid contact clarification

The purpose of the solid contact clarification is the same as the sedimentation process – to enhance the filtration process by removing particulates. It involves mixing the influent flow with settled solids within a cylinder located in the centre of the clarifier.

Gentle mixing promotes agglomeration of floc particles and chemical precipitates. The aggregated solids settle more rapidly in the clarification area.

Greater clarity is achieved when particles become enmeshed in a sludge blanket layer. Rotating sludge scrapers transport settled solids to the centre of the basin for removal. Clarified overflow is removed through a circular launder system that draws water from the entire surface area to prevent solids carryover caused by uneven velocity currents.

Step 4. Diffused air flotation

The process of flotation consists of 3 steps:

- bubbles form

- bubbles attach to the solids

- solids separate from the fluid.

Air is pressurised under several atmospheres and then introduced into water, where it’s mixed with pre-coagulated water just before it enters the flotation tank.

When air bubbles attach to the solid particles, the density of the solid becomes less than that of the surrounding fluid. Solids are lifted to the surface to form a scum blanket, which is automatically skimmed and discharged into a scum trough.

Step 5. Filtration

Filtration occurs as the water passes through filters that help remove particles that have not settled in the sedimentation process. Sand filters are commonly used in the water treatment process and may contain layers of gravels, sands and filter coal.

The sand filtration process removes fine suspended solid matter as well as some other particles, including larger micro-organisms. This results in clear water passing through.

Step 6. Disinfection

The water is disinfected to kill any pathogens (disease-causing organisms) that remain in the treated water after filtration and to provide protection within the distribution system.

Without disinfection, there is a much greater risk of waterborne disease. All of our water treatment plants use chlorination (with chlorine gas) to disinfect the water.

Step 7. Fluoridation

Water fluoridation is the adjustment of fluoride in drinking water to a level that helps protect teeth against dental decay. We fluoridate 11 of our drinking water supplies. Murrabit, Koondrook and Piangil are not fluoridated.

Fluoridation of the drinking water supplies is a requirement of the Health (Fluoridation) Act 1973.

Step 8. pH correction

The addition of coagulants and chlorine lowers the pH level of the water – it becomes more acidic.

The pH level is raised to 7.0 (neutral) by adding lime or other alkaline chemicals such as soda ash or sodium hydroxide. This helps to prevent corrosion and makes the water safe to use.

Monitoring and testing

We monitor our water to make sure the water delivered to our customers meets water quality standards.

Water samples are collected from treatment plants and customer taps. The samples are tested by an independent laboratory that is accredited by the National Association of Testing Authorities (NATA) and approved by the Victorian Department of Health.

Microbiological tests

Water is tested to make sure it’s free from micro-organisms that can cause disease. These tests measure the presence of E. coli and the total number of coliforms, or bacteria, which indicate possible contamination from sources such as human or animal waste. Water is also tested for Cryptosporidium and Giardia.

Physical and chemical tests

The physical characteristics of water relate to its appearance, taste, odour and ‘feel’, as well as the corrosion or scaling potential of the water.

Physical testing includes colour, turbidity and pH. Turbidity is a measure of the number of particles present in the water (high turbidity causes a cloudy appearance).

Chemical tests are conducted for a range of substances, including chlorine and other disinfection by-products and aluminium. These tests identify substances that may be naturally occurring or added to the water during the treatment process for health or aesthetic purposes.

Water is also tested for a range of health-related inorganic and organic components as well as for pesticides and herbicides.

Risk management

A drinking water quality management plan encompassing hazard analysis and critical control points (HACCP), is in place for all our urban supplies.

HACCP is an internationally recognised system that identifies and manages significant risks at key points in the water production process.

Untreated water supplies

Not all water is treated or safe to drink. Untreated water supplies include some town water supplies, irrigation water and water extracted by private diverters.

See Safe drinking water to find out more about your town’s water supply.